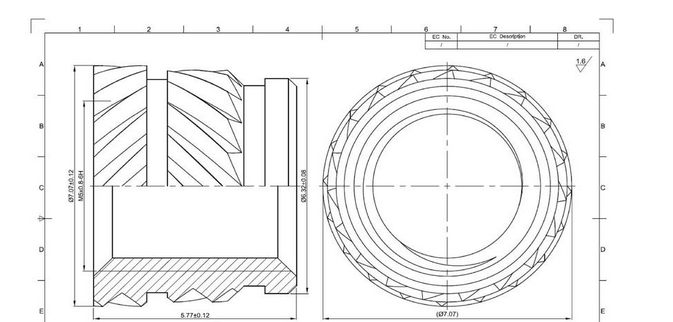

Cross Knurled Brass Inserts

Brass Hex Nuts are durable, corrosion-resistant fasteners commonly used in various industrial and construction applications. Manufactured to DIN 934 standards, these nuts provide secure fastening solutions for bolts and threaded rods. Ideal for environments where resistance to rust and weathering is crucial, brass hex nuts are both reliable and versatile, making them a preferred choice for long-term projects.

BrassMoldInsert is a leading manufacturer of Cross Knurled Brass Inserts in India, consistently using high-quality metals in production. Our company utilizes state-of-the-art machinery and a skilled workforce to produce top-grade metal fittings. Every product undergoes thorough quality testing to ensure it meets both domestic and international client standards. We specialize in developing custom Cross Knurling Supplements tailored to specific client requirements, offering various sizes and specifications to cater to industry demands. Just share your design or sample, and our expert engineers will select the ideal production method to meet your needs.

Features Cross Knurled Brass Inserts

- High tolerance

- Threads as per international go & not go standards

- Deep groove for maximum pull out resistance

Description of Cross Knurled Inserts

Material

- Brass, Copper, Stainless Steel, Steel

Application

- Suitable for installation with wide range of Thermoplastics, used where high pull out resistance is required.

- Used for fitting and fastening electronics products, surgical instruments, automotive parts and optical products.

- Ideal for use in punched or drilled holes.

Benefits:

- Double Ended, Assist Automatic Feeding, Increased Pull Out and Torque Performance.

- Self-Aligning and hence aid installation process.

- Increases products life span under operating condition without any fatal error.

- Tapered design reduces installation time.

- Exceptional Torque Strength is achieved as the insert’s knurled body expands filling the hole.

Operation:

- Install ultrasonically or with heat driver.

- Thread area is enclosed eliminating leakage past the threads from either side of the application.

- Superior Thread Strength is provided due to our internal rolled thread manufacturing process.

Typical Application:

Instrumentation, Telecommunications, Electrical Accessories, Electrical junction boxes and other Plastic Cases Assembly.

Finishing and Plating:

Natural, Nickle Platted, Chrome Platted, Tin Plated or any coating as per customer specifications.

BrassMoldInsert are manufacturer of threaded inserts for plastics. We involve an entire line of brass inserts for all method of fitting, as well as: heat, thermal, ultrasonic, and press-in and mold-in.

Instrumentation, Telecommunications, Electrical Accessories, Electrical junction boxes and other Plastic Cases Assembly.

- Begins from M2 or equivalent threads and up to any size as per Custom Designs and requirements.

- SO Metric (MM Threads)

- BA Threads

- BSW Threads (Inches)

- UNC, UNF Threads

- Any threads as per specifications.

Available in 5-10 days for different items.

CAD / PDF / DWG / IGS / STEP.

Standard package, Carton box or Pallet, As per customized specifications

DHL, FEDEX, UPS and By Sea or as per client’s requirements.

"From raw material selection and precision engineering to rigorous quality checks and final assembly, our manufacturing process ensures excellence at every step."

RAW MATERIAL SELECTION

MELTING

CHEMICAL ANALYSIS

BILLET CASTING

PRE HEATING

HOT EXTRUSION

PICKLING PROCESS

SHIPMENT

WEIGHING

PACKAGING BOXES

INSPECTION

MECHANICAL TESTING

STRAIGTENING

COLD DRAWING

Our happy customers

We’ve helped thousands of people move

Join the thousands who’ve effortlessly transitioned to their new homes with our expert moving services!

Codey Joyner

UrbanAcres, LLC

“My move was way less stressful than expected! Movely packed everything, stored it for a week, and moved it all to my new home just as promised!”

Eren Hill

H&H Legal Partners

“Movely provided a very professional service when we moved offices last month. They were easy to work with and moved everything on time.”

Emanuel Sadler

SavvyMarket

Best experience ever! I desperately needed a mover to help with a last minute relocation, and Movely was so helpful in making it a seamless process!”

We manufacture a wide range of brass components including but not limited to electrical parts, plumbing parts, automotive parts, precision turned parts, and fittings. We cater to various industries with specific customization needs.

Yes, our brass parts comply with various international standards such as ASTM, DIN, BS, and ISO. We are committed to providing products that meet or exceed our customers’ expectations.

To place a custom order, you can contact us directly through our website or email. Provide us with your detailed specifications and requirements, and our team will assist you throughout the process.

We handle international shipping through reliable logistics partners. We provide all necessary documentation and ensure compliance with export regulations for a smooth delivery process.

We offer comprehensive after-sales support including technical assistance, replacement of defective parts, and guidance on product usage. Our customer service team is always available to help with any queries.

You can reach our customer support team via phone, email, or through the contact form on our website. We aim to respond to all inquiries within 24 hours.