Brass Moulding Inserts

Metal Trim Supplements Brass Moulding Inserts provide a secure and reliable hold in plastic applications, made from high-quality metal alloys and available in various sizes. They can be installed using push-fit, ultrasonic, or heat methods. These inserts are widely used across multiple industries, including automotive, electronics, construction, and plastic injection molding. Kaizen Metals India specializes in producing these inserts in OEM specifications, customized according to client drawings or models. These parts are versatile and crucial for ensuring strong, lasting connections in diverse applications.

A latch that offers a protected and trustworthy hold in a plastic application is Metal Trim Supplements Brass Moulding Inserts.

They are worked from an exceptional metal combination and are accessible in a scope of sizes to address various issues.

They can be embedded utilizing a push, a ultrasound, or intensity another way.

Metal trim supplements nuts are many times used in different areas, including electrical, car, PC, wood, marine, and development, as well as plastic infusion forming. BrassMoldInserts are utilized in the development of building materials, plastic infusion forming, oceanic gear, and electrical parts.

These parts are accessible from us in different sizes and details as an OEM metal addition producer.

To start, you supply the sketch or model, and we will wrap up.

Types of Inserts:

Thermal Inserts

Heat Set Inserts

Ultrasonic Inserts

Press-In Inserts

Flowsert Blind Inserts

Flange Head Inserts

Symmetrical Inserts

Cross knurled Inserts

Non-Knurled symmetrical Inserts

Straight knurled inserts

Full diamond knurl inserts

Brass Threaded Inserts

Moulding Inserts

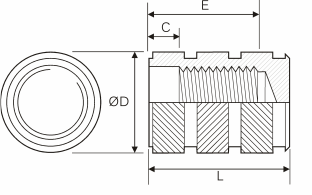

Products Range Moulding Inserts

Brass Hexagonal Inserts, Brass Square Inserts, Brass Molding / Moulding Inserts, Brass Heat inserts, Brass Inserts With Collar, Brass Press-in Inserts, Brass Cutting Thread Inserts, Brass Double Knurling Inserts, Brass Inserts For Plastic, Brass Inserts For Laptop etc.

OEM Services:

Custom design accepted.

Design as customer’s requirements offered.

Free sample before manufacturing provided.

Tolerance: With tight tolerance ±0.005 specific tolerances can be discussed with the customer, given the part material, size, and geometry.

Application: Plastic molding injection , Telecommunications, Laptop, Electrical, Automobile and Instrumentation.

Surface Treatment: Natural Clean / Nickel Plated / Electro-Tin Plated / Silver Plated / Copper Plated / Zinc Plated / Chrome Plated / Specified Surface Finish.

Brass Alloy: CuZn39Pb3 / CuZn39Pb2 / CuZn38Pb1.5 / CuZn37Pb2 / CuZn40Pb2 / MS 58 / BS2874 / IS 319 (Type I & II) UNS (ASTM): C35300 / C35330 DZR / C36000 (CDA 360) / C36500 / C37000 / C37100 / C37700 / C37710 / C38500 BS: CZ121 / CZ122 / CZ124 / CZ128 / CZ 131 / CZ132 EN: CW602N / CW603N / CW606N / CW608N / CW612N / CW614N / CW617N JIS: C3601 / C3602 / C3603 / C3604 / C3605 / C3712 / C3771 Any special brass material compositions as per customer’s requirements.

Sizes available from M2 to M30 and up to M36, and as per Custom Designs and requirements.

ISO Metric (MM) / BA / BSW / BSP / BSPT / BSF / BSB / UNC / UNF / UNEF / NPT / NPS / Specified Threads Any threads as per client specification.

Available in 5-10 days for different items.

CAD / PDF / DWG / IGS / STEP.

Standard package, Carton box or Pallet, As per customized specifications

DHL, FEDEX, UPS and By Sea or as per client’s requirements.

"From raw material selection and precision engineering to rigorous quality checks and final assembly, our manufacturing process ensures excellence at every step."

RAW MATERIAL SELECTION

MELTING

CHEMICAL ANALYSIS

BILLET CASTING

PRE HEATING

HOT EXTRUSION

PICKLING PROCESS

SHIPMENT

WEIGHING

PACKAGING BOXES

INSPECTION

MECHANICAL TESTING

STRAIGTENING

COLD DRAWING

Our happy customers

We’ve helped thousands of people move

Join the thousands who’ve effortlessly transitioned to their new homes with our expert moving services!

Codey Joyner

UrbanAcres, LLC

“My move was way less stressful than expected! Movely packed everything, stored it for a week, and moved it all to my new home just as promised!”

Eren Hill

H&H Legal Partners

“Movely provided a very professional service when we moved offices last month. They were easy to work with and moved everything on time.”

Emanuel Sadler

SavvyMarket

Best experience ever! I desperately needed a mover to help with a last minute relocation, and Movely was so helpful in making it a seamless process!”

We manufacture a wide range of brass components including but not limited to electrical parts, plumbing parts, automotive parts, precision turned parts, and fittings. We cater to various industries with specific customization needs.

Yes, our brass parts comply with various international standards such as ASTM, DIN, BS, and ISO. We are committed to providing products that meet or exceed our customers’ expectations.

To place a custom order, you can contact us directly through our website or email. Provide us with your detailed specifications and requirements, and our team will assist you throughout the process.

We handle international shipping through reliable logistics partners. We provide all necessary documentation and ensure compliance with export regulations for a smooth delivery process.

We offer comprehensive after-sales support including technical assistance, replacement of defective parts, and guidance on product usage. Our customer service team is always available to help with any queries.

You can reach our customer support team via phone, email, or through the contact form on our website. We aim to respond to all inquiries within 24 hours.