Earth Rod Couplers

Brass Hex Nuts are durable, corrosion-resistant fasteners commonly used in various industrial and construction applications. Manufactured to DIN 934 standards, these nuts provide secure fastening solutions for bolts and threaded rods. Ideal for environments where resistance to rust and weathering is crucial, brass hex nuts are both reliable and versatile, making them a preferred choice for long-term projects.

The Earth Rod Couplers electrodes we provide are thought to be the most popular earthing equipment because of their better resistance to oxidation.

This kind of copper electrode, along with Flat-in-Pipe technology, copper bonding, and the crystalline material poured inside the electrode, guarantees a grounding system that is both efficient and affordable.

We produce these electrodes in a range of sizes and specs while taking into account the various grounding needs.

A lightning strike generates fault current, which has a significant potential to harm the electrical components. Both human life and electrical systems are damaged by it.

Thus, the grounding or earthing system has become very necessary to disperse the fault current and protect priceless electrical and electronic equipment.

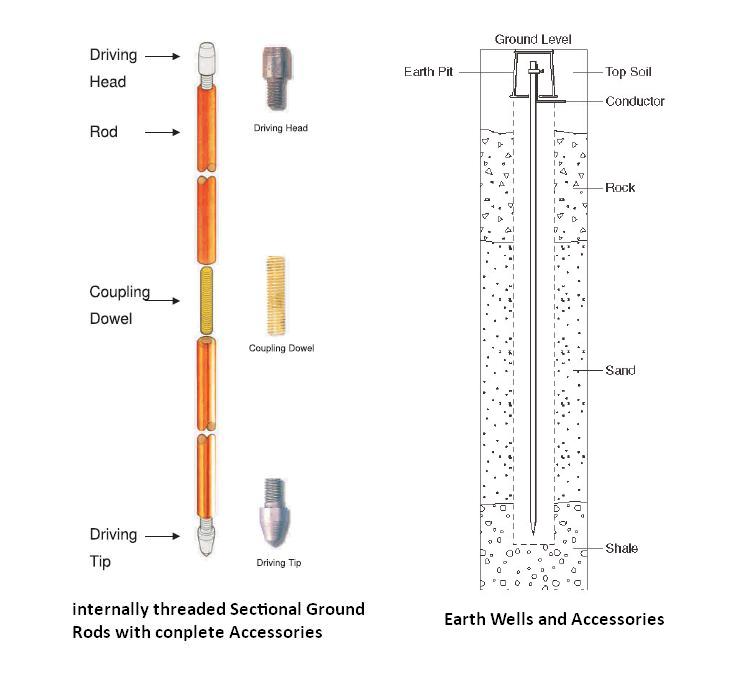

Made by molecularly connecting a core of low carbon steel with 99.9% pure electrolytic copper. Power hammers may be used to drive them to vast depths since they are very corrosion-resistant and the steel utilized has a very high tensile strength.

The best driven earth electrodes are Rod To Cable Clamps because they give the installer an affordable and effective earth rod grounding method.

A minimum thickness of 0.254 mm of pure electrolyte copper is evenly molecularly bonded into a high tensile steel core, guaranteeing superior corrosion resistance and obviating the need for electrolysis.

To guarantee thread strength and maintain the integrity of the molecularly bound copper, coupling threads are created by a rolling process.

Earth Rod Couplers Description

Features of Earth Rod Couplers:

Available in five different sizes and materials.

Material: High Copper Content Alloy/Silicon Aluminium Bronze

Standard: BS 7430, BS:EN 62561-2: 2012

More Information:

For installing lightning earthing system applications, We recommend the use of Copper earth electrode systems due to their inherent low resistivity and corrosion resistance.

Materials used in earthing systems must be able to:

- withstand mechanical damage,

- resist corrosion,

- provide a low impedance path to earth,

- and carry the maximum fault condition for the application/installation.

For protective earth networks and lightning protection applications our range encompasses:

Copper earth rod, earthing pole, copper bonded ground rod, earth ground rod, earth rod connector, earth rod cover, earth fitting, earthing studs, ground clamps for ground rod, ground pole and grounding post.

Our castings are high quality/high copper content complying to BS 7430 and BS 62561-1. Additional to our range are UL listed copper bond earth rods and exothermic welding.

Different Name :Earth Rod Couplers,Earth Rod With Coupling Joint Male-Female,Furse Coupling for Copperbond Earth Rods,Couplings (Copper bond Earth Rods)

Standard: BS 7430, BS:EN 62561-2: 2012

Size Description Earth Couplers

Standard:

| DESCRIPTION | |||

|---|---|---|---|

| Rod Coupling 5/8″ UNC | |||

| Rod Coupling 3/4″ UNC |

Hexagonal:

| DESCRIPTION | |||

|---|---|---|---|

| 16mm Rod Coupling 5/8″ UNC (HEX) | |||

| 20mm Rod Coupling 3/4″ UNC (HEX) |

Silicone Bronze:

| DESCRIPTION | |||

|---|---|---|---|

| 5/8” Rod Coupling |

Material: High Copper Content Alloy/Silicon Aluminium Bronze

Available in 5-10 days for different items.

CAD / PDF / DWG / IGS / STEP.

Standard package, Carton box or Pallet, As per customized specifications

DHL, FEDEX, UPS and By Sea or as per client’s requirements.

"From raw material selection and precision engineering to rigorous quality checks and final assembly, our manufacturing process ensures excellence at every step."

RAW MATERIAL SELECTION

MELTING

CHEMICAL ANALYSIS

BILLET CASTING

PRE HEATING

HOT EXTRUSION

PICKLING PROCESS

SHIPMENT

WEIGHING

PACKAGING BOXES

INSPECTION

MECHANICAL TESTING

STRAIGTENING

COLD DRAWING

Our happy customers

We’ve helped thousands of people move

Join the thousands who’ve effortlessly transitioned to their new homes with our expert moving services!

Codey Joyner

UrbanAcres, LLC

“My move was way less stressful than expected! Movely packed everything, stored it for a week, and moved it all to my new home just as promised!”

Eren Hill

H&H Legal Partners

“Movely provided a very professional service when we moved offices last month. They were easy to work with and moved everything on time.”

Emanuel Sadler

SavvyMarket

Best experience ever! I desperately needed a mover to help with a last minute relocation, and Movely was so helpful in making it a seamless process!”

We manufacture a wide range of brass components including but not limited to electrical parts, plumbing parts, automotive parts, precision turned parts, and fittings. We cater to various industries with specific customization needs.

Yes, our brass parts comply with various international standards such as ASTM, DIN, BS, and ISO. We are committed to providing products that meet or exceed our customers’ expectations.

To place a custom order, you can contact us directly through our website or email. Provide us with your detailed specifications and requirements, and our team will assist you throughout the process.

We handle international shipping through reliable logistics partners. We provide all necessary documentation and ensure compliance with export regulations for a smooth delivery process.

We offer comprehensive after-sales support including technical assistance, replacement of defective parts, and guidance on product usage. Our customer service team is always available to help with any queries.

You can reach our customer support team via phone, email, or through the contact form on our website. We aim to respond to all inquiries within 24 hours.