Brass Pipe Flanges

Brass Pipe flanges are flat, circular plates that are used in plumbing and piping systems to join pipes, valves, and other piping parts. flanges They normally come in a range of forms and sizes to suit various purposes and are made of brass, a metal that is very corrosion-resistant.

Additionally, they are utilized to stabilize and support a piping system as well as to fasten or seal a pipe or component in place. Bolts are used to tighten two brass flanges together, forming a reliable and leak-proof seal, to link them.

Brass Pipe flanges are flat, circular plates that are used in plumbing and piping systems to join pipes, valves, and other piping parts. flanges They normally come in a range of forms and sizes to suit various purposes and are made of brass, a metal that is very corrosion-resistant.

Additionally, they are utilized to stabilize and support a piping system as well as to fasten or seal a pipe or component in place. Bolts are used to tighten two brass flanges together, forming a reliable and leak-proof seal, to link them.

Brass alloys can have different elemental elements depending on the desired qualities, unlike certain copper alloys that have a set chemical makeup. Many Brass Flanges Suppliers select a replacement alloy because of this. Brass tarnishes easily, much like copper alloys do. Applying a small coating of oil to the component’s outside surface will help prevent tarnish. Any Brass Flanges maker in India will also employ a lacquer coating as a secondary means of preventing the component from becoming tarnished. Normally, the flange’s lacquer covering would be transparent. Brass has a number of advantages despite tarnishing.

Corrosion is not a problem for the Brass Companion Flange, even in saltwater conditions. Ordinary steel alloys are susceptible to deterioration in saltwater, when the sodium chloride concentration is saturated at 3.5%. However, Brass Pipe Flanges are regarded as performing well in maritime conditions, particularly in terms of galvanic corrosion.

Any component that has been put in saltwater is susceptible to galvanic corrosion, which is a common problem on oil rigs. Its alloy, unlike some others, benefits from the presence of copper since it prevents bacterial development. It is therefore perfect for usage as a Brass Closet Flange. In actuality, brass is thought to have better corrosion resistant qualities than copper.

The Brass Threaded Flange’s strong corrosion resistance is improved by the inclusion of zinc, which is a metal in and of itself. Because it is a substitution alloy, zinc concentration might change. Less zinc is required for applications that call for more ductility. However, the amount of zinc in its chemical makeup must be much larger for a harder Brass Pipe Floor Flange.

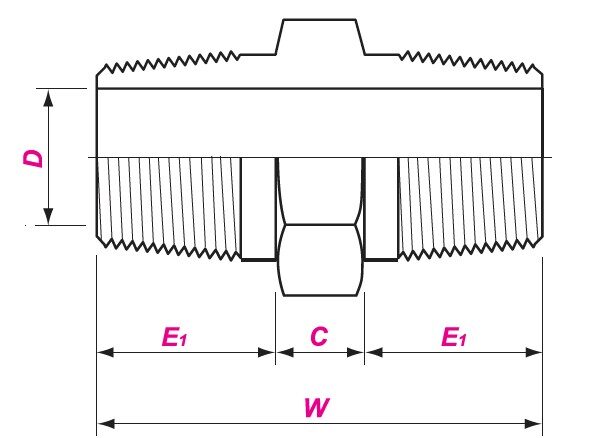

Brass Pipe Flanges Description

Products Range: Pipe Flanges, Floor Flanges, Open Flanges, Blank Flanges, Companion Flange, Blind Flanges, Threaded Flanges, Slip-on Flanges, Socket Flanges, Weld Neck Flanges

Materials:

Brass Alloy: CuZn39Pb3 / CuZn39Pb2 / CuZn38Pb1.5 / CuZn37Pb2 / CuZn40Pb2 / MS 58 / BS2874 / IS 319 (Type I & II)

UNS (ASTM): C35300 / C35330 DZR / C36000 (CDA 360) / C36500 / C37000 / C37100 / C37700 / C37710 / C38500

BS: CZ121 / CZ122 / CZ124 / CZ128 / CZ 131 / CZ132

EN: CW602N / CW603N / CW606N / CW608N / CW612N / CW614N / CW617N

JIS: C3601 / C3602 / C3603 / C3604 / C3605 / C3712 / C3771

Any special brass material compositions as per customer’s requirements.

OEM Services:

Custom design accepted.

Design as customer’s requirements offered.

Free sample before manufacturing provided.

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, and 3″ OR as per custom requirements.

Tolerance: With tight tolerance ±0.005 specific tolerances can be discussed with the customer, given the part material, size, and geometry.

Application: Plastic molding injection , Telecommunications, Laptop, Electrical, Automobile and Instrumentation.

Dimension: Sizes available from M2 to M30 and up to M36, and as per Custom Designs and requirements.

Threads: ISO Metric (MM) / BA / BSW / BSP / BSPT / BSF / BSB / UNC / UNF / UNEF / NPT / NPS / Specified Threads Any threads as per client specification.

Surface Treatment: Natural Clean / Nickel Plated / Electro-Tin Plated / Silver Plated / Copper Plated / Zinc Plated / Chrome Plated / Specified Surface Finish.

Keyword:Brass Pipe Flanges,metal flanges, brass flanges, brass pipe flanges, brass flange fittings, brass companion flanges, brass blind flanges, brass threaded flanges, brass slip-on flanges, brass Socket flanges, brass weld neck flanges

Products Range: Pipe Flanges, Floor Flanges, Open Flanges, Blank Flanges, Companion Flange, Blind Flanges, Threaded Flanges, Slip-on Flanges, Socket Flanges, Weld Neck Flanges

Size: 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, and 3″ OR as per custom requirements.

Threads: ISO Metric (MM) / BA / BSW / BSP / BSPT / BSF / BSB / UNC / UNF / UNEF / NPT / NPS / Specified Threads Any threads as per client specification.

Available in 5-10 days for different items.

CAD / PDF / DWG / IGS / STEP.

Standard package, Carton box or Pallet, As per customized specifications

DHL, FEDEX, UPS and By Sea or as per client’s requirements.

"From raw material selection and precision engineering to rigorous quality checks and final assembly, our manufacturing process ensures excellence at every step."

RAW MATERIAL SELECTION

MELTING

CHEMICAL ANALYSIS

BILLET CASTING

PRE HEATING

HOT EXTRUSION

PICKLING PROCESS

SHIPMENT

WEIGHING

PACKAGING BOXES

INSPECTION

MECHANICAL TESTING

STRAIGTENING

COLD DRAWING

Our happy customers

We’ve helped thousands of people move

Join the thousands who’ve effortlessly transitioned to their new homes with our expert moving services!

Codey Joyner

UrbanAcres, LLC

“My move was way less stressful than expected! Movely packed everything, stored it for a week, and moved it all to my new home just as promised!”

Eren Hill

H&H Legal Partners

“Movely provided a very professional service when we moved offices last month. They were easy to work with and moved everything on time.”

Emanuel Sadler

SavvyMarket

Best experience ever! I desperately needed a mover to help with a last minute relocation, and Movely was so helpful in making it a seamless process!”

We manufacture a wide range of brass components including but not limited to electrical parts, plumbing parts, automotive parts, precision turned parts, and fittings. We cater to various industries with specific customization needs.

Yes, our brass parts comply with various international standards such as ASTM, DIN, BS, and ISO. We are committed to providing products that meet or exceed our customers’ expectations.

To place a custom order, you can contact us directly through our website or email. Provide us with your detailed specifications and requirements, and our team will assist you throughout the process.

We handle international shipping through reliable logistics partners. We provide all necessary documentation and ensure compliance with export regulations for a smooth delivery process.

We offer comprehensive after-sales support including technical assistance, replacement of defective parts, and guidance on product usage. Our customer service team is always available to help with any queries.

You can reach our customer support team via phone, email, or through the contact form on our website. We aim to respond to all inquiries within 24 hours.