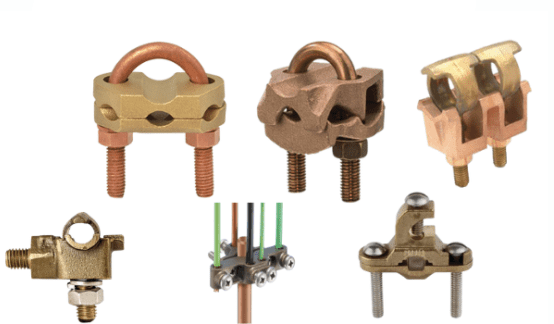

Grounding and Bonding

Grounding and Bonding are essential practices for ensuring safety and preventing static electricity buildup that can lead to fires. Grounding connects electrical systems to the earth for stability, while bonding ensures electrical continuity between components like aircraft and ground equipment. These processes safeguard personnel, prevent electric shocks, and protect sensitive equipment from interference. Proper bonding and grounding are critical for safety, functionality, and production efficiency in various applications, including industrial and aviation settings.

Providing an electrically conductive path between a dispensing container, a receiving container, and an earth ground is known as Grounding and Bonding.

This prevents the buildup of static electricity and sparks that could start a flash fire if fuel and air are mixed in a flammable way.

Therefore, the differences between bonding and earthing can be summarized as follows: Earthing is the stuff ‘in’ the ground, and; Holding is the stuff ‘over the’ ground.

Consequently, knowing that some “stuff” from the earthing system will be above ground level.

The purpose of the grounding (earthing) procedure is to ensure that the aircraft and the ground remain electrically connected.

Bonding with electricity: The holding activity is for the electrical congruity between the airplane and a ground gear, or between a hardware and the airplane structure.

Earthing is essentially used to stay away from electric shocks.

When the electric system overloads, grounding is primarily used to unbalance the system.

Earthing is situated between the gear body and the underground pit under the earth pit.

Connecting electrical equipment to a common reference ground or earth is known as grounding.

Safeguarding is utilized for resistance (safeguarding against outside obstruction) and discharge (forestalling impedance to be emanated).

The personnel’s safety within a building comes first. The electrical system’s proper bonding and grounding could be the reason an employee in the building doesn’t get shocked accidentally and can go home that night. That much is at stake.

Sensitive equipment and low-voltage signals are two additional items that could be harmed by improper bonding and grounding. Despite the fact that these items may be related to safety, their usability is also essential to production.

Categorize of Grounding and Bonding

Available in 5-10 days for different items.

CAD / PDF / DWG / IGS / STEP.

Standard package, Carton box or Pallet, As per customized specifications

DHL, FEDEX, UPS and By Sea or as per client’s requirements.

"From raw material selection and precision engineering to rigorous quality checks and final assembly, our manufacturing process ensures excellence at every step."

RAW MATERIAL SELECTION

MELTING

CHEMICAL ANALYSIS

BILLET CASTING

PRE HEATING

HOT EXTRUSION

PICKLING PROCESS

SHIPMENT

WEIGHING

PACKAGING BOXES

INSPECTION

MECHANICAL TESTING

STRAIGTENING

COLD DRAWING

Our happy customers

We’ve helped thousands of people move

Join the thousands who’ve effortlessly transitioned to their new homes with our expert moving services!

Codey Joyner

UrbanAcres, LLC

“My move was way less stressful than expected! Movely packed everything, stored it for a week, and moved it all to my new home just as promised!”

Eren Hill

H&H Legal Partners

“Movely provided a very professional service when we moved offices last month. They were easy to work with and moved everything on time.”

Emanuel Sadler

SavvyMarket

Best experience ever! I desperately needed a mover to help with a last minute relocation, and Movely was so helpful in making it a seamless process!”

We manufacture a wide range of brass components including but not limited to electrical parts, plumbing parts, automotive parts, precision turned parts, and fittings. We cater to various industries with specific customization needs.

Yes, our brass parts comply with various international standards such as ASTM, DIN, BS, and ISO. We are committed to providing products that meet or exceed our customers’ expectations.

To place a custom order, you can contact us directly through our website or email. Provide us with your detailed specifications and requirements, and our team will assist you throughout the process.

We handle international shipping through reliable logistics partners. We provide all necessary documentation and ensure compliance with export regulations for a smooth delivery process.

We offer comprehensive after-sales support including technical assistance, replacement of defective parts, and guidance on product usage. Our customer service team is always available to help with any queries.

You can reach our customer support team via phone, email, or through the contact form on our website. We aim to respond to all inquiries within 24 hours.