Pendent Sprinklers

A Pendent Sprinklers is installed at the pipeline’s terminus to spray water to put out or suppress the fire. From the ceiling, a protruding pendent sprinkler hangs down.

Water that emerges from the orifice shoots downward because it has a water deflector built into the bottom of the device. In business or residential buildings, pendent sprinklers are frequently employed.

A Pendent Sprinklers is installed at the pipeline’s terminus to spray water to put out or suppress the fire. From the ceiling, a protruding pendent sprinkler hangs down.

Water that emerges from the orifice shoots downward because it has a water deflector built into the bottom of the device. In business or residential buildings, pendent sprinklers are frequently employed.

At the end of the firefighting pipeline, a fire sprinkler for firefighting systems is installed to spray water on the fire to put it out or suppress it.

From the ceiling, a protruding pendent sprinkler hangs down. Water that emerges from the orifice shoots downward because it has a water deflector built into the bottom of the device.

In commercial or residential structures, pendent sprinkling is frequently employed. Nationally recognized safety standards, FM listed, and Ul listed. various sizes starting from 1/2″ and going up to 3/4″ are available.

Sprinklers that are pendent or upright are intended to be used in low-risk situations. Standard response (5mm glass bulb) and fast response (3mm glass bulb) are the two temperature responses.

The glass bulb type, compact form, and range of finishes and temperature specifications are all features of the sprinklers.

Sprinklers that are pendent must be put in that position, and sprinklers that are upright must be installed in that position.

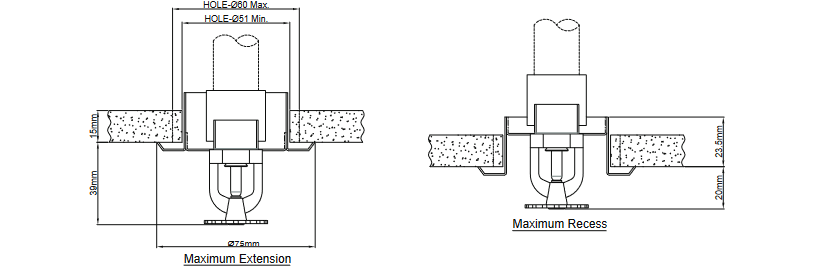

Escutcheon plates, also known as Rosette plates, are used to place pendent recessed sprinklers. These plates can be adjustable or non-adjustable. The installation of these is meant to be done with completed ceilings.

Escutcheon plate adjustment makes installing Pendent Sprinklers easier in spaces with completed walls or ceilings.

Pendent Sprinklers Description

STYLE Upright, Pendent and Recessed Pendent

TEMPERATURE Standard Response- 5mm

RESPONSE glass bulb Quick Response- 3mm glass bulb

COVERAGE Standard Coverage

K-FACTOR 5.6 US (80 metric)

NOMINAL THREAD ½” BSPT (NPT Optional)

SIZE MAXIMUM WORKING 175 psi (12 bar)

PRESSURE FACTORY 500 psi (35 bar)

HYDROSTATIC TEST PRESSURE

MINIMUM 7 psi (0.5 bar)

OPERATING

PRESSURE

TEMPERATURE 57°C (135° F), 68°C (155° F),

RATING 79°C (175° F), 93°C (200° F),

141°C (286°F),182°C (360°F)

FINISH Brass, Chrome Plated, White Painted. White shade is RAL9010. For other shades,

ORDERING Style,Temperature Rating &

INFORMATION Response,Thread type, Finish, Approval required- UL or UL & FM

Size Description Pendent

| No. | Size | Galv/Black | Des |

| 55-5110 | 1/2″ | — | K-F 5.6/Brass |

| 55-5111 | 3/4″ | — | K-F 8.1/Brass |

| 55-5210 | 1/2″ | — | K-F 5.6/Chrome |

| 55-5211 | 3/4″ | — | K-F 8.1/Chrome |

| 55-5311 | 3/4″ | — | K-F 8.1/Brass |

Size Description Pendent

| No. | Size | Galv/Black | Des |

| 55-5110 | 1/2″ | — | K-F 5.6/Brass |

| 55-5111 | 3/4″ | — | K-F 8.1/Brass |

| 55-5210 | 1/2″ | — | K-F 5.6/Chrome |

| 55-5211 | 3/4″ | — | K-F 8.1/Chrome |

| 55-5311 | 3/4″ | — | K-F 8.1/Brass |

STYLE Upright, Pendent and Recessed Pendent

Available in 5-10 days for different items.

CAD / PDF / DWG / IGS / STEP.

Standard package, Carton box or Pallet, As per customized specifications

DHL, FEDEX, UPS and By Sea or as per client’s requirements.

"From raw material selection and precision engineering to rigorous quality checks and final assembly, our manufacturing process ensures excellence at every step."

RAW MATERIAL SELECTION

MELTING

CHEMICAL ANALYSIS

BILLET CASTING

PRE HEATING

HOT EXTRUSION

PICKLING PROCESS

SHIPMENT

WEIGHING

PACKAGING BOXES

INSPECTION

MECHANICAL TESTING

STRAIGTENING

COLD DRAWING

Our happy customers

We’ve helped thousands of people move

Join the thousands who’ve effortlessly transitioned to their new homes with our expert moving services!

Codey Joyner

UrbanAcres, LLC

“My move was way less stressful than expected! Movely packed everything, stored it for a week, and moved it all to my new home just as promised!”

Eren Hill

H&H Legal Partners

“Movely provided a very professional service when we moved offices last month. They were easy to work with and moved everything on time.”

Emanuel Sadler

SavvyMarket

Best experience ever! I desperately needed a mover to help with a last minute relocation, and Movely was so helpful in making it a seamless process!”

We manufacture a wide range of brass components including but not limited to electrical parts, plumbing parts, automotive parts, precision turned parts, and fittings. We cater to various industries with specific customization needs.

Yes, our brass parts comply with various international standards such as ASTM, DIN, BS, and ISO. We are committed to providing products that meet or exceed our customers’ expectations.

To place a custom order, you can contact us directly through our website or email. Provide us with your detailed specifications and requirements, and our team will assist you throughout the process.

We handle international shipping through reliable logistics partners. We provide all necessary documentation and ensure compliance with export regulations for a smooth delivery process.

We offer comprehensive after-sales support including technical assistance, replacement of defective parts, and guidance on product usage. Our customer service team is always available to help with any queries.

You can reach our customer support team via phone, email, or through the contact form on our website. We aim to respond to all inquiries within 24 hours.